Cabin sound levels vary greatly between different types of aircraft. So when we talk about quiet cabins, we have to keep in mind that there are significant variations based on size, engine type, and use of the airplane.

If you are a pilot and like to get around in a small, single-engine airplane, you will probably be exposed to sound levels in the 90 – 100 dBA range (see Aircraft Insulation Basics for a primer on cabin sound level measurements). In these environments, pilots and passengers generally wear headsets to protect their ears and to be able to converse. We usually do not see much of an effort to make these cabins quieter, since even with a fairly significant reduction in noise levels, the headsets would still be required.

On a commercial airliner, the cabin is usually kept at a (barely) comfortable 65 – 80 dBA, allowing conversation with the person next to you, but not much more than that. OSHA requires that workers use some form of personal protection equipment when exposed to sound levels in excess of 85 dBA, so airlines have to make sure that their flight attendants are not exposed to noise above that threshold for extended periods of time. But other than that, there is not much of an incentive for additional cabin soundproofing.

Corporate aircraft, however, are completely different. If you travel on the company jet for business, then business is what is expected of you, and reducing cabin sound levels becomes more important.

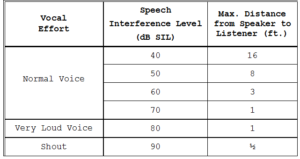

Part of the challenge in this context is accurately measuring the results of cabin noise reduction efforts, so we will digress here for a minute to talk about some of the terms used in acoustics. dB SIL (Speech Interference Level) has become the most commonly used metric for efforts related to producing quieter aircraft cabin interiors and to measure the effectiveness of aircraft cabin soundproofing systems. In addition to the simple dbA measurements, SIL is calculated for various locations in the airplane during flight. SIL (3) is the Speech Interference Level, calculated as the arithmetic mean of unweighted sound pressure levels in three octave bands – the 1000, 2000 & 4000 Hz frequency ranges.

Since that does not mean much to most non-acousticians, the following chart should help. It shows the approximate distance at which a person could still be understood given different background noise levels:

Business jets these days of the Gulfstream or Global Express variety are delivered with average cabin sound levels of 55 to 60 dB SIL, which allow comfortable conversations and conference calls. Most importantly, they also help passengers arrive at their destinations without the fatigue induced by noisy environments.

Step up to the Boeing Business Jet, Airbus A-320 or larger private aircraft, and we are now in the realm of sitting rooms with state-of-the-art surround sound systems, offices, conference rooms and bedrooms. Owners of these aircraft often demand the same environment they have at home or in their private office – a requirement that can be attained, as long as a number of trade-offs are considered.

First of course there is the cost of the insulation system, but that is generally minimal in comparison to the price of the aircraft and its VIP completion effort. More importantly though, cabin noise reduction is generally associated with a weight penalty.

The most effective way to treat noise is to add mass, which of course decreases range and raises fuel consumption. Part of our challenge here at Luminary is to constantly identify and test new materials that offer beneficial acoustic properties without adding a disproportionate amount of weight. Constant improvements in materials help us improve the noise/weight trade-off.

Owners who want to achieve the lowest possible sound levels also have to consider the acoustic properties of the surfaces used in their cabin interior. Hard surfaces in the interior allow noise to get “bounced” around the cabin more.

A final point here is consistency of noise levels throughout the cabin. We have heard of completions with cabin SIL’s of 46 dB SIL or lower, but in most cases those are limited to individual rooms in the aircraft, not averages throughout. A significant difference between a quiet bedroom and a noisy hallway and other rooms of varying noise levels can actually feel uncomfortable because it draws attention to the sound. A BBJ with consistent levels of 48 – 50 dB SIL or even 50 – 52 dB SIL may not set records, but is extremely quiet and comfortable when there is no noticeable difference between the individual rooms on the aircraft.

Finding the right balance

Cabin noise reduction will (almost) never be the only consideration for interior modifications. The key is to find the right balance between design preferences, weight and cost. Luminary Air Group, using the latest technology in acoustic analysis, has the capability to pinpoint noise sources, external, internal and mechanical, thereby minimizing the locations of heavier treatments and allowing the design of a cabin comfort system that provide levels specific to customer requirements, including extremely quiet rooms. Because, after all, the customer is always right.